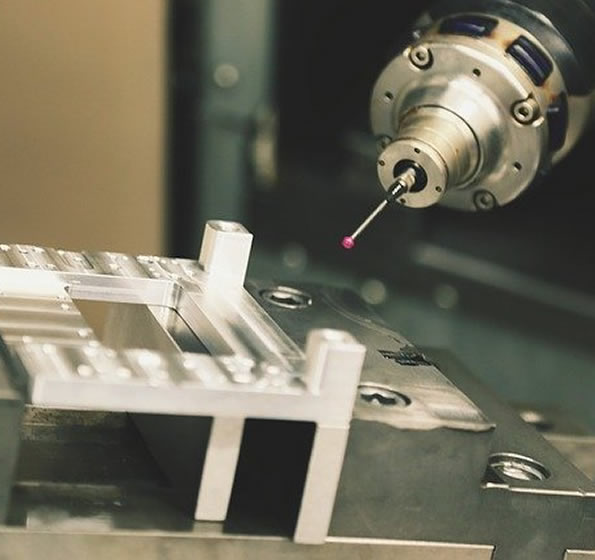

Our company maintains a very low scrap and reject rate. We make parts with exotic metals and high nickel alloys as well as common metals. We also are capable of machining castings made of cast iron, aluminum, steel, and stainless steel. We take pride in being able to machine parts that are complicated and require close tolerances. We machine parts on a daily basis with 0.0003” – 0.0005” tolerances.

We are capable of running prototype or production items as needed per our customers’ orders. Our consistent quality precision work with both CNC and manual equipment allows us to keep up with the changing demands of our customers.

Request a quote using our online form!

In order to produce quality parts for our customers, our company maintains equipment capable of producing high quality machined parts. We are capable of lifting parts up to 5,000 pounds. Our equipment includes the following:

CNC Lathes

- Ecoca SJ35/HT 12” Chuck

- Mori-Seiki TL5-B 12” Chuck 78” between centers

- Mori-Seiki SL3 8” Chuck

- Mighty Viper 6” Chuck

- Doosan Puma 300LC – Turning Center

- ProtoTrax 18” x 45” CNC Lathe

CNC Mills

- DPMX 7 23” x 60” ProtoTrax CNC MIll

- OKK V5-2 4 Axis with 50 Taper Spindle 40” x 20”

- Milltronics RH30 60” x 30” 3 Axis

- Milltronics RH30 60” x 30” 3 Axis

- Hass VF 2 30” x 16” 3 Axis

Manual Machinery

- Clausing Kondia FV-1 Milling Machine

- Kingston HR4000 34” x 168” Lathe

- DeVlieg 28-36 Spiramatic Jigmil

- Select 22” x 80” Engine Lathe

- Brown and Sharpe 8” x 24” Surface Grinder

- Morrison 1 ¼” Keyset Cutter

- Sunnen Hone with Mandrel

- Dual Chamber Heat Treat Furnace

- 75 Ton H-Frame Press

- Hyd Mech 14” Horizontal Band Saw

- Grob 20” Vertical Band Saw

Usage rights of select images on this page:

cnc-lathe.jpg By Somesomething243 – Own work, CC BY-SA 4.0, https://commons.wikimedia.org/w/index.php?curid=48832695 – Modified from original.